The Best Cars Made in South Africa

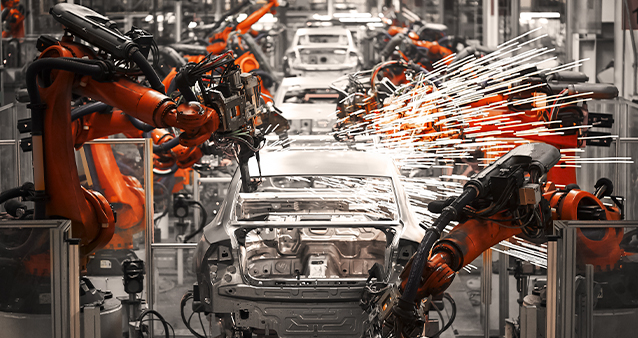

Did you know that South Africa isn't just mad about cars, we make them too? From reliable bakkies to luxury cruisers in East London, we’ve become a major player in the global automotive manufacturing and assembly game. We’re not just putting cars on our roads: we’re sending them off to Germany, Japan, the UK, and beyond.

Did you know that South Africa isn't just mad about cars, we make them too? From reliable bakkies to luxury cruisers in East London, we’ve become a major player in the global automotive manufacturing and assembly game. We’re not just putting cars on our roads: we’re sending them off to Germany, Japan, the UK, and beyond.

Here’s your ultimate guide to the cars proudly built or assembled in South Africa. Discover a quick list below, then keep reading to explore where they're made, how they’re made, and what the future of home-grown vehicle manufacturing looks like.

List of Cars Made in South Africa

- Ford Ranger - Pretoria

- Toyota Hilux, Hiace, Fortuner, Corolla Cross, Corolla Quest - Durban

- VW Polo, Polo Vivo and Amarok - Uitenhage

- Mercedes-Benz C-Class - East London

- Nissan Navara - Pretoria

- Isuzu D-Max - Port Elizabeth

- BMW X3 - Pretoria

- Mahindra Pik Up - Durban

- Hyundai EX8 and H100 – Johannesburg

- BAIC Beijing X55, BJ40 and BJ30 – Gqeberha

- Chery Tiggo 4 Pro – Gqeberha

- GWM P-Series – Pretoria

- Haval Jolion – Pretoria

- Kia 2700 - Pretoria

Cars Manufactured or Assembled in South Africa

Ford Ranger: Pretoria

The Silverton Assembly Plant in Pretoria has been building Fords since the 1960s. These days, it’s all about the Ford Ranger. This locally built legend is manufactured from scratch and exported to over 100 markets, including Europe.

The plant underwent a R15.8 billion upgrade recently to ramp up volume and create over 1,200 new jobs. Plus, there's the Tshwane Automotive Special Economic Zone (TASEZ) next door, which is drawing local suppliers into the fold and giving the economy a proper shot in the arm.

Toyota Hilux, Hiace, Fortuner, Corolla Cross and Corolla Quest: Durban

Toyota’s Prospecton plant in KwaZulu-Natal is an institution. Since opening shop in 1962, it’s produced over 1.5 million vehicles and is one of the busiest plants on the continent. This is where the Toyota Hilux, is made, alongside the Fortuner and the Corolla Cross.

Prospecton is also known for being the first to build hybrid cars on African soil, with the Corolla Cross Hybrid now rolling out locally. Toyota exports vehicles from here to over 40 countries in Africa, Latin America, and Europe.

VW Polo, Polo Vivo and Amarok: Uitenhage

Kariega (formerly Uitenhage) is home to Volkswagen’s longest-running plant outside Germany, going strong since 1951. More than 4 million cars have rolled out of this iconic Eastern Cape factory, including classics like the Citi Golf and Kombi.

Today, it’s the Polo and Polo Vivo that take centre stage. These are manufactured from the ground up, and the Polo especially is a massive export hit, heading to markets like the UK, Ireland, and Australia. VW South Africa also plays a major role in supplier development and has invested heavily in training and local enterprise.

Volkswagen has announced a R4 billion investment to introduce a third model, the VW Tera compact SUV, set to be built in South Africa from 2027.

Mercedes-Benz C-Class: East London

Over in East London, the Mercedes-Benz plant has been producing vehicles since 1958. Not just the C-Class, but a proud lineup of earlier models too, including the iconic Ponton series, the W110 and W111 "Fintail", the W114 and W115, and even the W116 and W124.

Today, the factory is the only one outside Germany entrusted with manufacturing the C-Class sedan.

The plant celebrated its one-millionth C-Class back in 2015 and keeps exporting to over 80 countries. This facility has created thousands of jobs and built a thriving ecosystem of local suppliers, making it a jewel in South Africa’s automotive crown.

Nissan Navara: Pretoria

The Rosslyn plant has been Nissan’s South African home since 1966 and was recently upgraded with a R3 billion investment to kick off local manufacturing of the Nissan Navara. The plant used to assemble the NP200 and NP300, but today it's all about the new-gen Navara. A bakkie built here for the local market and over 40 export destinations.

This facility also plays a role in community upliftment, including a skills centre focused on youth development and local sourcing initiatives that support black-owned suppliers.

Isuzu D-Max: Port Elizabeth

The Isuzu plant in Gqeberha (formerly Port Elizabeth) is now wholly operated by Isuzu, it manufactures the beloved D-Max bakkie (previously the KB) and has received over R1.2 billion in investment to keep the factory world-class.

It’s not just bakkies for South African roads either. The D-Max is exported to 25 African countries, and Isuzu has become a major employer in the Nelson Mandela Bay region. The plant supports local suppliers and aims to source parts locally where available.

BMW X3: Pretoria

BMW’s Rosslyn plant, established in 1973, was the first outside Germany and has built some of the rarest BMWs in history including the South Africa-only 333i, which is a collector’s dream today.

It now manufactures the BMW X3 SUV for local and global markets, including the US, Japan, and the UK. The plant hit its one-millionth unit milestone in 2015 and is a showcase of advanced robotics, local supplier integration, and sustainable production.

Mahindra Pik Up: Durban

Mahindra set up its semi-knocked down (SKD) assembly plant in the Dube TradePort SEZ in 2018. It may be newer than most on this list, but the Mahindra Pik Up is fast gaining fans thanks to its ruggedness and affordability.

The plant assembles around 5,000 units a year and aims to source around 40% of its components locally, supporting job creation and black-owned suppliers in the process.

Hyundai EX8 and H100: Johannesburg

The Hyundai Evehicles are assembled in a R110 million facility on the East Rand and supplies units across southern Africa.

The focus is on commercial vehicles rather than passenger cars, but the investment has helped create jobs and secure local parts contracts, particularly in Gauteng’s industrial supply chain.

BAIC Beijing X55, BJ40 and BJ30: Gqeberha

The BAIC Beijing X55 is assembled at BAIC’s state-of-the-art plant in the Coega Special Economic Zone near Gqeberha, Eastern Cape. Opened as a joint venture between China’s BAIC Group and South Africa’s Industrial Development Corporation, the facility represents the largest new automotive investment in post-apartheid South Africa and was designed for high automation and scalability.

Production of the Beijing X55 began in late 2022 with the updated X55 Plus introduced in 2024, marking BAIC’s commitment to long-term growth in the South African market. The X55 features modern turbo powertrains, advanced technology, and a striking exterior design. The plant focuses on local assembly and parts localisation, supporting suppliers and creating jobs in the region as it ramps up to full capacity.

Chery Tiggo 4 Pro: Gqeberha

Chery’s Tiggo 4 Pro is one of the most popular compact SUVs on South African roads and has contributed to Chery’s dramatic local growth. Assembly takes place in Gqeberha (formerly Port Elizabeth), reflecting the new wave of Chinese automakers investing in the South African automotive landscape.

The Tiggo 4 Pro has quickly captured market share thanks to its strong value proposition, modern safety tech, and an unmatched 10-year/1 million km engine warranty. With flexible assembly lines and local supplier integration on the rise, the Gqeberha plant underlines the region’s importance as a manufacturing and logistics hub for both domestic sales and future exports.

GWM P-Series: Pretoria

The GWM P-Series bakkie is assembled at the Bahrsfontein vehicle assembly plant in Gauteng, partnering both with local and Chinese stakeholders. This modern facility focuses on bringing robust, affordable 1-ton pickups to South African buyers who demand both value and capability.

Plant investments have helped introduce advanced manufacturing techniques, while localisation initiatives are strengthening the supply chain and creating jobs in the Rosslyn industrial corridor.

Haval Jolion: Pretoria

Haval’s Jolion compact SUV, one of the country’s best-sellers in its class, is also assembled near Rosslyn in the Bahrsfontein plant alongside the GWM P-Series. Assembly is tailored for the southern African market, with input from local suppliers and continuous investment in skills development.

This new wave of production demonstrates the growing significance of Chinese brands and their commitment to establishing a long-term footprint in South Africa’s auto industry.

Kia K2700: Pretoria

The immensely practical Kia K2700 workhorse is assembled at a dedicated facility in Rosslyn, a hub renowned for commercial vehicle manufacturing.

The site supports extensive local business activity and skills training in Gauteng’s automotive sector, with the K2700 remaining a favourite among small businesses and fleet owners looking for reliable transport and affordable maintenance.

EVs and the Future of Car Manufacturing

Electric vehicles (EVs) are coming in hot, and South Africa is gearing up. NAAMSA’s New Energy Vehicle Roadmap aims to position SA as a serious EV player on the continent.

For now, the only local EV production confirmed is at Ford’s Silverton plant, which is preparing for EV-ready facilities. Volkswagen has also hinted at introducing electric models in Kariega, and the Tshwane SEZ is expected to become a hub for EV parts and batteries.

With Eskom’s grid stabilising (slowly but surely) and policy support growing, South Africa could be building EVs for Africa and the world within the decade.

Compare, Save, Repeat

If your car is built in SA, you’re already part of a pretty cool club. But remember to make sure you’re not overpaying to keep it covered. Use our car insurance comparison tool to get quotes from multiple providers in minutes.

You can also compare other car cover solutions, like service plans, motor warranty or scratch and dent cover. All in one place and within minutes.

Hippo Blog Categories